Almost Zero failure rate. Our equipment function consistently without failing. Your maintenance team can relax.

Simplicity is the ultimate sophistication. Our simple systems are easy to troubleshoot, operate and maintain.

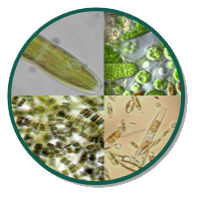

At the forefront of the algae field, we have innovated many systems and lead many projects

The systems are built only after detailed application study. Making sure that our systems perform as per your needs.

With experience in multiple product lines we can alter the systems to suit your specific need be it oil or fertilizers

All your micro algae technological needs at one place. No problems of integration of different equipment's.

We were among the first to extract

specialty lipids from algae and ran trials for Stearidonic acid many years ago. From then on we have

built up capabilities of cultivation for Omega oil, EPA and DHA extraction

using photo heterotrophic systems.

With our teams experience in both pilot

and commercial scale implementation along with our proprietary process line of

downstream processing we have the

perfect solution to develop your algae to lipid venture.

We use pulsed electric field and

solvent extraction as our choice of system for oil extraction. Refining is then

carried out for required component appropriately.

Our upstream consists of seed scale PBR

and then high rate algae ponds for cultivation using our low cost nutrient

media. The concentration of the algae is done using our harvesting and

dewatering systems.

We have successful cultivated Dunaliella and extracted beta carotene from it.

Our staff have multiple experiences both in pilot scale and in commercial scale

of scale of over 3 hectares or 10 acres

of cultivation area.

The advantageous of our solutions i.e low cost of harvesting, nutrients, reliable culture and high

quality nutrient retention apply to this algae as well.

Our Dunealliella solutions offer:

We will help you in every step of the way from design to QC to certifications to make sure your algae venture is successful.

Combining the expertise in low cost Spirulina cultivation along with our extraction experience we are able extract not only very high quality CPC but do it cost effectively.

In one of our projects we are combining effluent treatment with CPC extraction! We call the project waste to color!

Our CPC process is very simple, it’s both easy to maintain and has very little downtime.

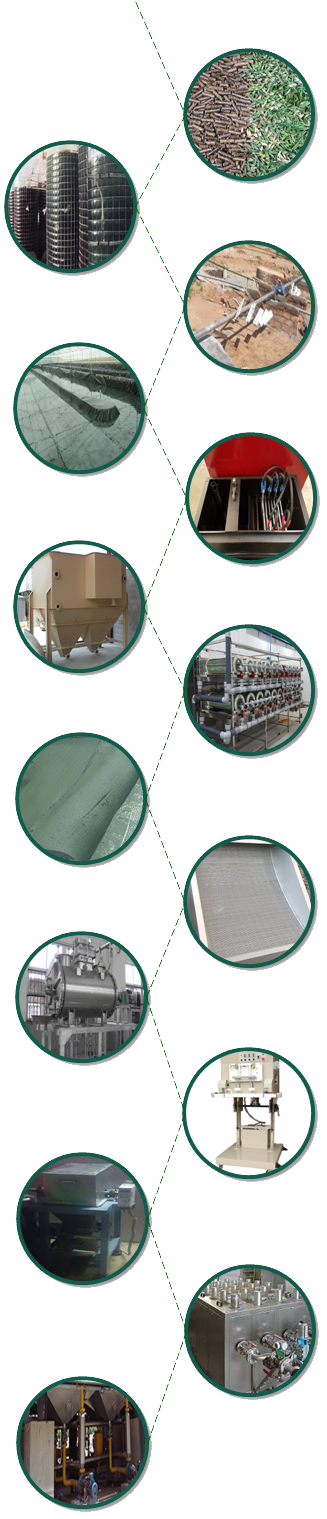

Low cost PBR systems, PE based simple PBR systems for starting culture.

Long lasting raceway liner or membranes.

Flocculation systems for small cell algae. (less than 20 micron)

Vacuum dewatering or thickening of algae to increase drying efficiency etc.

Vacuum drying, spray drying, convection drying options for algae and sludge drying

Powdering systems such as bead mills and hammer mills

Extraction vessels for solvent and water based extraction.

Nutrients organic and inorganic for your microalgae.

High efficiency Agitators for your Raceway ponds.

Electro-coagulation systems for small celled algae (less than 20 micron).

Harvesting systems for larger celled algae like spirulina, desmids, AFA etc.

Prefilters and settlers for your unintended suspended solids

Vacuum and nitrogen flush packing.

Cell wall rupturing systems like bead mills, ultrasonication and homogenizers.